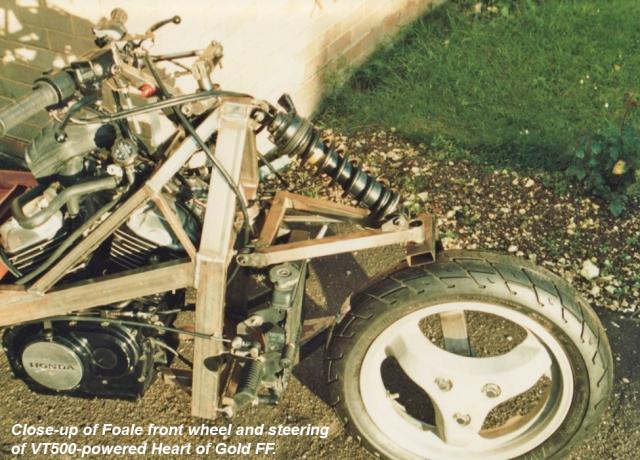

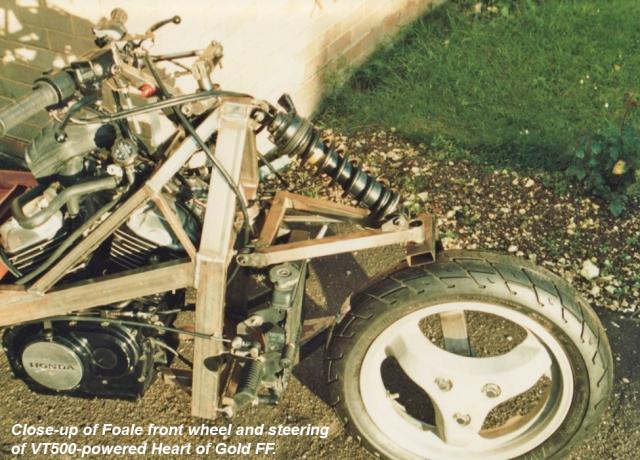

Foale Front wheel & steering

Close-up of the Foale front wheel, plus 'homemade' steering and front suspension of Heart of Gold, plus the radiator, right footrest and Honda VT500 engine. PNB

Photo: Tim Rowledge archive

FF WebFeet Forward people do it Feet First |

||

NavigationRecent blog postsBook navigationWho's onlineThere are currently 1 user and 11 guests online.

Online users

|

Foale Front wheel & steeringClose-up of the Foale front wheel, plus 'homemade' steering and front suspension of Heart of Gold, plus the radiator, right footrest and Honda VT500 engine. PNB  |

Strut location

While being ignorant of the design process that led to this choice, I question the location of the suspension strut onto the top wishbone. This feeds suspension loads through the wishbone joint and the upright, which need to be stressed to carry this load. Convention* is that it's preferrable to put suspension loads through the bottom ball joint, which carries the major loads and is stressed accordingly. This is done by connecting the strut to the lower arm, close to it's outer end and the bottom ball joint, thus removing suspension loads from the rest of the system. This in turn means the upright and top wishbone only have to carry the relatively trivial loads imposed by brake torque and steering reaction and these unsprung parts can then be lighter and smaller.

To put this in perspective the upright and top wishbone on the Voyager HCS, (similar, even if double sided), uses the smallest automotive ball joints that could be found (Metro/Rover 100)and apart from some that suffered boot failure and water ingress, have never worn out, The original inner wishbone joints on FJ are still stiff enough to hold the wishbone up when disconnected from the upright. FJ actually uses a Ford Cargo Gearlever balljoint as an outer wishbione joint, which requires ocasional greasing but is now easily twenty years old and has no free movement. (Later units use a waterproof Mercedes ball joint similar to the Metro unit but with a more convenient male thread). Difazio units use a stock 3/8th.UNF rod end joint for all the upper joints. These suffer from some free play and lack angularity, limiting lock, but are amply strong anough. Meanwhile the relatively massive bottom ball joint in the Voyager wheel centre, which does carry suspension loads, develops free pay after "only" 50,000 miles. Difazio and Tait systems also put suspension loads through the bottom 'ball joint', as does the Yamaha (GTS) copy of Tony's 'arm and wishbone' system.

It might be argued that the strut location shown here removes the strut from the side of the wheel where it might reduce leg space, but most 'double wishbone' systems run the struts alongside the wheel (Voyagers, Phazars, many one-offs) so it can be done with careful packaging. It also makes the top strut location easier to integrate with the inner wishbone and steering pickups, thus saving some more wieght. And it lowers the height of the strut.

*I'm a very conventional designer. Always looking for the shoulders of a giant to stand on and pay the compliment of imitation. Avoid innovation where possible, it's expensive and risky!

Heart of Gold top-front suspension arm

Hi Royce,

well, what can I say? Not all that much, actually since it was all a very long time ago!

Part of the design was driven by what we could obtain of course, and back then with no internet it was more than a bit tricky to find stuff you didn't already know much about. We went with a fairly plain ball joint I already had from an attempt at building a sort-of-difazio hub whilst at Imperial. You're quite correct that it probably wasn't the sort for a long life with the forces we were exposing it to.

Using a top arm with the suspension loads passed through it seemed the best option at the time because it avoided making the lower single sided arm too massive. And of course we had the inspiration of Tony Foale's QL front end; after all we were using one of his wheels. One could argue that the arm needed to be stronger/heavier anyway to handle siddeloads and braking forces without distorting too much, but as always it was we could do at the time. The vertical strut was definitely something I remember us discussing a lot. We would have cast one if that had seemd at all practical.

There probably isn't much I'd do the same if I had a chance to try again. Right now I'm occasionaly musing about a front setup I could best describe as plunger-hub-centre. The old plunger back ends were terrible but these days we have computer controlled suspension and I reckon one could do some interesting things with active control of each side of the wheel separately managed.